The Difference between Embossing and Debossing ?

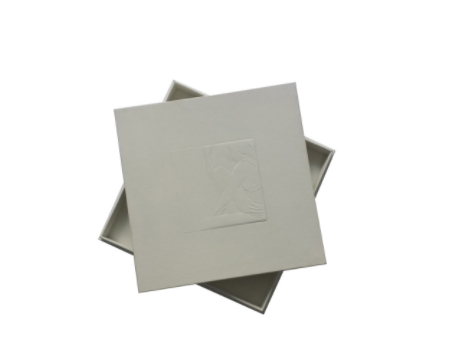

The rigid shoulder box above is an underwear packaging box. The pretty girl on the lid is debossed with fine details for the socks

What is Embossing and Debossing

Debossing and embossing are used to imprint images onto paper, leather, or vinyl and are widely used on the luxury packaging, like the cosmetic paper boxes, luxury paper bags and rigid boxes. In embossing, an image is pressed into the material so that the image raises from the surface. Debossing is the opposite of embossing; the area around the image is pressed so that the image is pushed down into the material rather than raised.

To emboss an image, a logo or artwork must be used as a template in order to cut a metal die and a corresponding counter-die. Dies are made of brass, copper, or magnesium. Brass dies are stronger and they will last longer with repeated use. They are used for multi-level and detailed designs, such as an imprint of a human face. Copper, though usually cheaper than brass, will not withstand as many impressions and it will not be as effective for multi-level printing. Magnesium is much weaker than brass and copper, and it is used one time for simple, single-level impressions.

The Process of Embossing and Debossing

To begin the embossing process, the material is fit between the two dies and a press and heat are used to squeeze the die imprint into the material. The result is a raised and exact copy of the logo or artwork. The embossed area is smooth because the heat and pressure act like an iron.

The straight tuck end paper box above is a cosmetic.

packaging box with the debossing for the brand logo.

This is a custom luxury paper box with the logo text.

debossed. Meantime, the logo text is logo matte silver foil stamped.

Previous: Printing shop talks about what is packaging printing

Next: No More